Tele:086-158 5277 8516

Tele:086-133 9518 0897

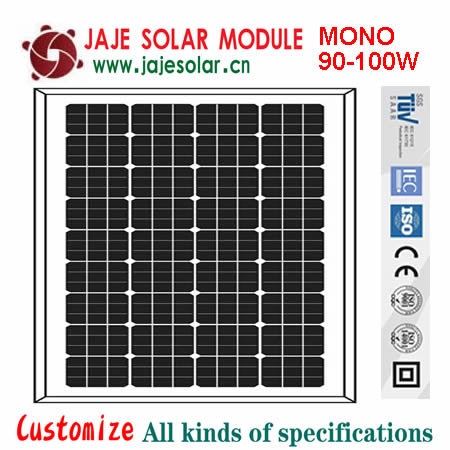

90-100W mono solar module

90-100W mono solar module

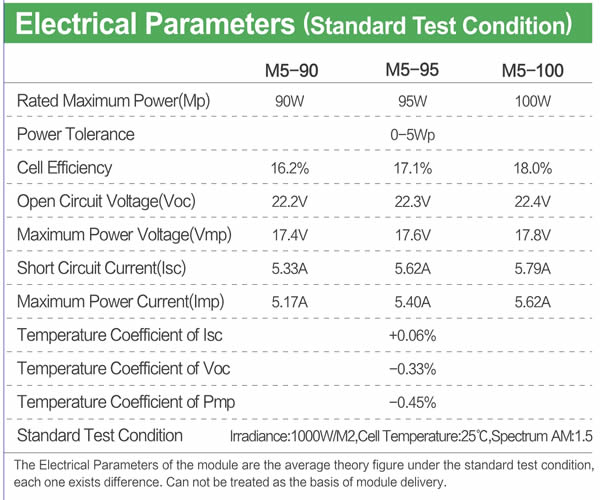

Power Pmax 90-100W

peak power Pmax 90-100W

operating current Imp 5.17-5.62A

working voltage Vmp 17.40-17.80V

short-circuit current Isc 5.33-5.79A

open-circuit voltage Voc 22.2-22.4V

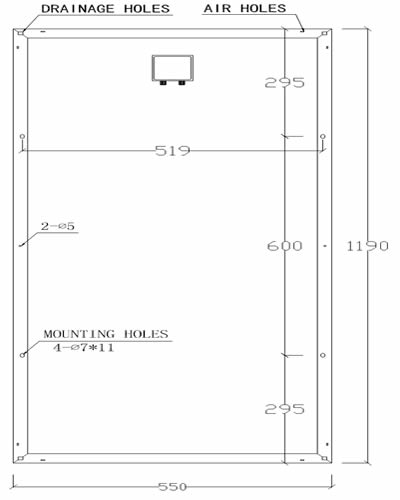

module external dimensions Dimension: 1190*550*30mm

module weight Weight: 8KG

type of cxells: mono 125*125

battery piece arranges Arrangement 4*9

- Detailed description

JAJE 90-100W mono solar module

Power Pmax 90-100W

peak power Pmax 90-100W

operating current Imp 5.17-5.62A

working voltage Vmp 17.40-17.80V

short-circuit current Isc 5.33-5.79A

open-circuit voltage Voc 22.2-22.4V

module external dimensions Dimension: 1190*550*30mm

module weight Weight: 8KG

type of cxells: mono 125*125

battery piece arranges Arrangement 4*9

The solar panels are designed according to the CE requirements of the International Electrotechnical Commission, and 60 or 72 monocrystalline silicon solar cells are connected in series to form various components of 12V and 24V. This component can be used for various household photovoltaic systems, independent photovoltaic power stations and grid connected photovoltaic power stations.

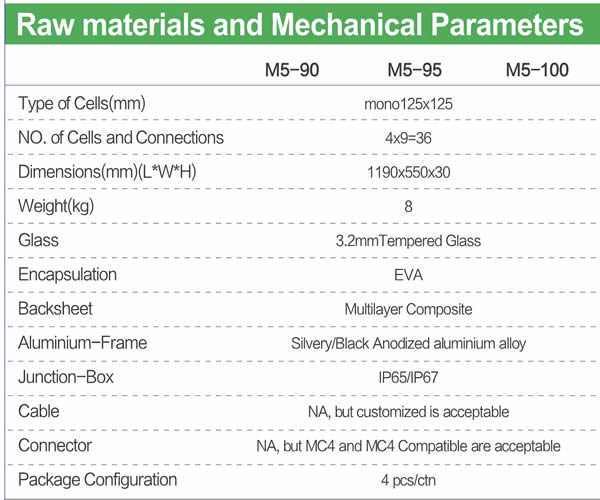

Characteristics of raw materials:

Battery sheet: the high efficiency (more than 17%) single crystal silicon solar panels are used to ensure that the power of the solar panels is sufficient.

Tempered glass: the glass surface (also known as Bai Boli), the thickness of 3.2mm, in the wavelength range of the solar cell spectral response (320-1100nm) in the light transmission rate of more than 91%, the reflectivity is higher for the more than 1200 nm infrared light. At the same time, the glass can resist the radiation of ultraviolet light from the sun, and the transmittance does not decrease.

Solar panel EVA: a high quality EVA film with a thickness of 0.78mm added with anti ultraviolet agent, antioxidant and curing agent is used as the sealant of the solar cell and the connection agent between glass and TPT. It has high light transmittance and anti aging ability.

Solar panel: TPT solar cell back cover of fluorine plastic film is white, the sun has reflection function, so the efficiency of components increased slightly, and because of its high infrared emissivity, can reduce the working temperature of the component, but also conducive to improving the efficiency of assembly. Of course, the fluoroplastic film first has the basic requirements for aging, corrosion resistance and air permeability required by the packaging materials of the solar cell.

Frame: the aluminum alloy frame used is of high strength and strong resistance to mechanical impact.

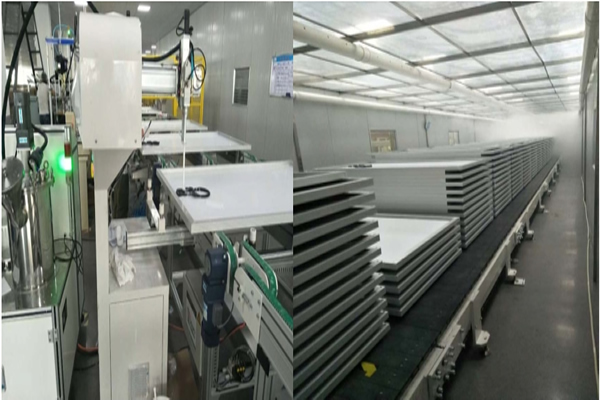

Equipment assembly production line includes: typesetting machine, conveyor, component feeding machine, EL testing machine (including pre and final inspection), IV testing machine, turning machine, automatic glue machine, automatic edge trimming machine, automatic box machine, stack machine group, curing line, sorting stacking machine and related components of photovoltaic testing experimental equipment. The project is advanced in equipment and high in automation, and is in the advanced level in the industry. At the same time, the assembly line layout is scientific, reasonable and beautiful, with a high cost performance and convenient operation and maintenance.

They are all searching: solar panels, solar modules, solar systems, solar stations, solar controllers, solar inverters

【Sweep, pay attention to us】

【Sweep, pay attention to us】