Tele:086-133 5790 4980

Tele:086-133 9518 0897

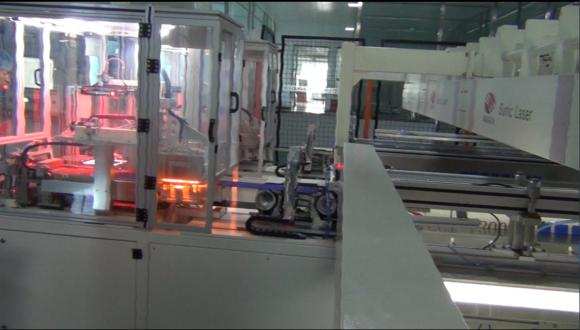

Production process

JajePhotovoltaic Module

Production process

Date of establishment: 1 March 2019

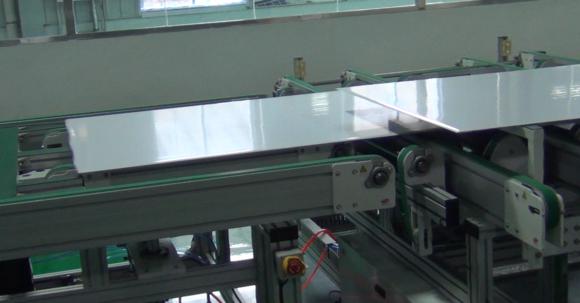

1.Placement of glass EVA

2.Series welding and typesetting

3.Layer buffer

4.Mirror inspection

5.Pre-Layer EL Detection

6.Lamination

7.Post layer transportation

8.Trimming

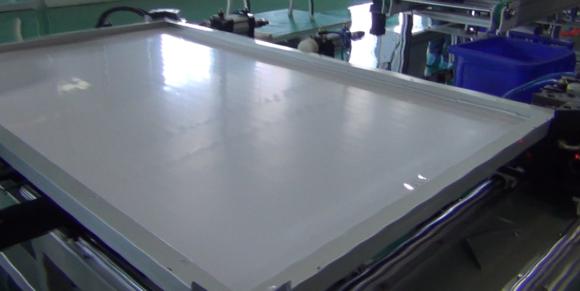

9.Gluing and binding

10.Terminal box

11.Natural curing

12.Clean

13.Final inspection

14.Final inspection package

15.finished product

How to Guarantee High Efficiency and Long Life of panels:

1、High Conversion Efficiency and High Quality solar cell;

2、High quality raw materials, such as EVA with high crosslinking degree, packaging agent with high bonding strength (neutral silica gel), tempered glass with high transmittance and high strength, etc;

3、Reasonable Packaging Technology

4、Strict working style of employees;

The module is composed of high conversion efficiency monolithic solar cells, anti-aging EVA film, high transmittance low iron tempered glass and Tedlar (TPT) back film composed of fluoroplastics and polyester. These components are heated and laminated under vacuum to form a whole. Finally, the anodized anti-corrosion aluminium alloy frame and junction box are installed to form the finished components. It has the characteristics of high efficiency, long service life, convenient installation, wind resistance and hail resistance.

【Sweep, pay attention to us】

【Sweep, pay attention to us】